3S-GSC

Ultrafiltration Plants

Water Treatment

Ultrafiltration Plants

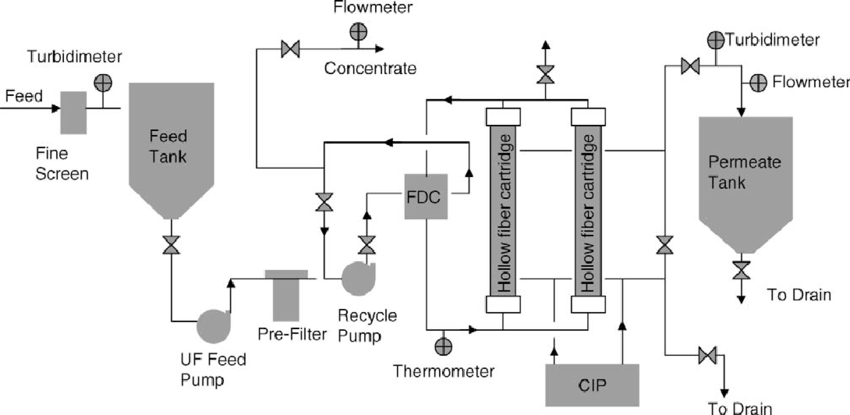

Ultrafiltration Plants are water treatment systems that use membranes to remove suspended solids, bacteria, viruses, and other contaminants from water. UF is a type of membrane filtration that uses a membrane with very fine pores (typically 0.01 to 0.1 microns) to separate suspended solids, colloids, and high molecular weight substances from water. UF membranes have a high surface area-to-volume ratio, which makes them very effective at removing contaminants from water.

UF plants are used for a variety of applications, including drinking water treatment, wastewater treatment, and industrial process water treatment. They are often used in combination with other treatment technologies, such as reverse osmosis (RO), to provide a complete water treatment solution.

The process of Ultrafiltration involves

UF involves passing water through a membrane under pressure. The membrane pores are sized so that they allow water molecules to pass through while blocking suspended solids, bacteria, and other contaminants. The filtered water is collected on the other side of the membrane, while the contaminants are retained on the membrane surface and periodically flushed away.

UF plants are relatively easy to operate and maintain, and they are very effective at removing a wide range of contaminants from water. They are also energy-efficient and have a small footprint, which makes them suitable for use in a variety of settings, including remote locations and small communities. However, UF membranes can become fouled over time, which can reduce their effectiveness and require periodic cleaning or replacement.

Ultrafiltration PLANTs Designs

DIFFERENT DESIGNS OF Ultrafiltration PLANTS

There are several different designs of UF plants, each with its own advantages and disadvantages.

Hollow fiber UF

In this design, hollow fiber membranes are used to filter the water. The membranes are bundled together in a module, and the water is passed through the hollow fibers. This design is commonly used in drinking water treatment, wastewater treatment, and industrial applications.

Spiral-wound UF

This design uses spiral-wound membranes that are wound around a central core. The water flows through the membrane channels, while the contaminants are retained on the membrane surface. Spiral-wound UF is commonly used in industrial process water treatment and some drinking water applications.

Tubular UF

This design uses tubular membranes that are arranged in a module. The water flows through the inside of the tubes, while the contaminants are retained on the membrane surface. Tubular UF is commonly used in industrial process water treatment and some drinking water applications.

Plate and frame UF

This design uses flat membrane panels that are stacked together in a frame. The water is passed through the membrane panels, while the contaminants are retained on the membrane surface. Plate and frame UF is commonly used in industrial process water treatment.

Immersed UF

In this design, the membranes are immersed in a tank or basin, and the water flows over the membrane surface. The contaminants are retained on the membrane surface and periodically removed. Immersed UF is commonly used in wastewater treatment and some industrial applications.

COME & TRY OUR SERVICES

contact us for more detail